- Heater

-

- Cartridge Heaters

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

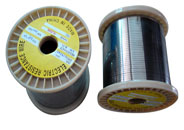

Eleatric Heating alloy

Nickel-chromium (NiCr) alloys

Nickel-chromium (NiCr) alloys

Nickel-chromium (NiCr) alloys' chemical composition is nickel,chromium and ferrum, it used at operating temperatures up to 1200 degree. Its chemical composition gives good oxidation resistance especially under conditions of frequent switching or wide temperature fluctuations.They are used for electric resistances of appliances or for application of industrial furnaces. Compare to ferrtic alloy, it has better resistance to oxidation,low embrittlement at high temperature, good plasticity (easier to give them a shape compared with FeCrAl. But the price is very more expensive than FeCrAl alloy.

Chemical Composition and Main Properties of Nickel-chromium (NiCr) alloys

Chemical Composition and Main Properties of Nickel-chromium (NiCr) alloys |

||||||||

Properties / Grade |

NiCr 80/20 |

NiCr 70/30 |

NiCr 60/15 |

NiCr 35/20 |

NiCr 30/20 |

|||

Main Chemical Composition(%) |

Ni |

Rest |

Rest |

Rest |

34.0-37.0 |

30.0-34.0 |

||

Cr |

20.0-23.0 |

28.0-31.0 |

15.0-18.0 |

18.0-21.0 |

18.0-21.0 |

|||

Fe |

≤1.0 |

≤1.0 |

Rest |

Rest |

Rest |

|||

Max Work Temp(℃) |

1200 |

1250 |

1150 |

1100 |

1100 |

|||

Resisivity 20(Ωmm2/m) |

1.09 |

1.18 |

1.12 |

1.04 |

1.04 |

|||

Density(g/cm3) |

8.4 |

8.1 |

8.2 |

7.9 |

7.9 |

|||

ThermalConductivity(KJ/m·h·℃) |

60.3 |

45.2 |

45.2 |

43.8 |

43.8 |

|||

Coefficient of Thermal Expansion(α×10-6/℃) |

18 |

17 |

17 |

19 |

19 |

|||

Melting Point(℃) |

1400 |

1380 |

1390 |

1390 |

1390 |

|||

Elongation(%) |

>20 |

>20 |

>20 |

>20 |

>20 |

|||

Micrographic Structure |

austenite |

austenite |

austenite |

austenite |

austenite |

|||

Magnetic Property |

nonmagnetic |

nonmagnetic |

nonmagnetic |

Weak magnetic |

Weak magnetic |

|||

A series of Ni-Cr,Ni-Cr-Fe alloys with their diameters and characteristics (Conversion Table)

Dia |

Cross sectional area |

Weight per Meter(kg/m) |

Resistance per meter at 20℃(Ω/m) |

||||||||||

OCr13Al4 |

OCr25Al5

OCr21Al6 |

Cr15Ni60 |

Cr20Ni80 |

Cr20Ni30 |

OCr13Al4 |

OCr25Al5

|

OCr27Al7 |

OCr21Al6 |

Cr15Ni60 |

Cr20Ni80 |

Cr20Ni30 |

||

| 0.1 | 0.0079 | 0.00006 | 0.00006 | 0.00006 | 0.00007 | 0.00006 | 160.4 | 178.3 | 191 | 183.5 | 131.6 | 140.1 | 141.3 |

| 0.2 | 0.0314 | 0.00023 | 0.00022 | 0.00026 | 0.00026 | 0.00025 | 40.13 | 44.59 | 44.77 | 46.17 | 33.12 | 35.01 | 35.33 |

| 0.3 | 0.0707 | 0.00052 | 0.0005 | 0.00058 | 0.00059 | 0.00056 | 17.82 | 19.8 | 21.22 | 20.5 | 14.71 | 15.56 | 15.7 |

| 0.4 | 0.01257 | 0.00093 | 0.00089 | 0.00103 | 0.00106 | 0.00099 | 10.02 | 11.14 | 11.93 | 11.53 | 8.27 | 8.75 | 8.83 |

| 0.5 | 0.1964 | 0.0015 | 0.0014 | 0.00161 | 0.00165 | 0.0016 | 6.416 | 7.128 | 7.638 | 7.382 | 5.295 | 5.604 | 5.655 |

| 0.6 | 0.2827 | 0.0021 | 0.002 | 0.00232 | 0.00237 | 0.0022 | 4.457 | 4.952 | 5.306 | 5.129 | 3.678 | 3.891 | 3.926 |

| 0.8 | 0.5027 | 0.0037 | 0.0036 | 0.00412 | 0.00422 | 0.0039 | 2.507 | 2.785 | 2.984 | 2.884 | 2.068 | 2.188 | 2.208 |

| 1 | 0.7854 | 0.0058 | 0.0056 | 0.0064 | 0.0066 | 0.0062 | 1.604 | 1.872 | 1.91 | 1.846 | 1.324 | 1.401 | 1.413 |

| 1.2 | 1.131 | 0.0084 | 0.008 | 0.0092 | 0.0095 | 0.0089 | 1.114 | 1.238 | 1.326 | 1.282 | 0.919 | 0.972 | 0.9814 |

| 1.4 | 1.539 | 0.011 | 0.011 | 0.0126 | 0.0129 | 0.0122 | 0.8187 | 0.9097 | 0.9747 | 0.9421 | 0.6757 | 0.7147 | 0.7212 |

| 1.6 | 2.011 | 0.015 | 0.014 | 0.0164 | 0.0169 | 0.0159 | 0.6266 | 0.6962 | 0.7459 | 0.721 | 0.5171 | 0.547 | 0.522 |

| 1.8 | 2.545 | 0.019 | 0.018 | 0.0209 | 0.0214 | 0.0201 | 0.4951 | 0.5501 | 0.5894 | 0.5697 | 0.4086 | 0.4322 | 0.4361 |

| 2 | 3.142 | 0.023 | 0.22 | 0.0257 | 0.0264 | 0.0248 | 0.401 | 0.4456 | 0.4775 | 0.4614 | 0.3309 | 0.3501 | 0.3533 |

| 2.2 | 3.801 | 0.028 | 0.027 | 0.0312 | 0.0319 | 0.03 | 0.3315 | 0.3683 | 0.3946 | 0.3814 | 0.2736 | 0.2894 | 0.292 |

| 2.4 | 4.524 | 0.033 | 0.032 | 0.037 | 0.038 | 0.036 | 0.2785 | 0.3095 | 0.3316 | 0.3205 | 0.2298 | 0.2431 | 0.2454 |

| 2.6 | 5.309 | 0.039 | 0.038 | 0.044 | 0.045 | 0.042 | 0.2373 | 0.2637 | 0.2825 | 0.2731 | 0.1958 | 0.2027 | 0.2091 |

| 2.8 | 6.158 | 0.046 | 0.044 | 0.05 | 0.052 | 0.049 | 0.2046 | 0.2273 | 0.2436 | 0.2354 | 0.1688 | 0.1786 | 0.1803 |

| 3 | 7.069 | 0.052 | 0.05 | 0.058 | 0.059 | 0.056 | 0.1782 | 0.198 | 0.2122 | 0.2051 | 0.1471 | 0.1556 | 0.157 |

| 3.2 | 8.043 | 0.06 | 0.057 | 0.066 | 0.068 | 0.064 | 0.1576 | 0.1741 | 0.1856 | 0.1802 | 0.1293 | 0.138 | 0.1386 |

| 3.5 | 9.621 | 0.071 | 0.068 | 0.079 | 0.081 | 0.076 | 0.131 | 0.1455 | 0.1559 | 0.1507 | 0.108 | 0.1143 | 0.1154 |

| 4 | 12.57 | 0.093 | 0.089 | 0.103 | 0.105 | 0.099 | 0.1002 | 0.1114 | 0.1193 | 0.1153 | 0.0827 | 0.0875 | 0.0883 |

| 4.5 | 15.9 | 0.118 | 0.113 | 0.13 | 0.134 | 0.126 | 0.0792 | 0.0881 | 0.0943 | 0.0911 | 0.0654 | 0.0691 | 0.0698 |

| 5 | 19.64 | 0.145 | 0.139 | 0.161 | 0.165 | 0.155 | 0.0642 | 0.0713 | 0.0764 | 0.0738 | 0.0529 | 0.056 | 0.0565 |

| 5.5 | 23.76 | 0.175 | 0.168 | 0.195 | 0.199 | 0.188 | 0.053 | 0.0589 | 0.0631 | 0.061 | 0.0437 | 0.0463 | 0.0467 |

| 6 | 28.27 | 0.209 | 0.201 | 0.232 | 0.237 | 0.223 | 0.0446 | 0.0495 | 0.0531 | 0.0512 | 0.0367 | 0.0389 | 0.0396 |

| 6.5 | 33.17 | 0.245 | 0.235 | 0.272 | 0.279 | 0.262 | 0.0376 | 0.0428 | 0.0461 | 0.0437 | 0.0313 | 0.034 | 0.0343 |

| 7 | 38.48 | 0.284 | 0.273 | 0.315 | 0.323 | 0.303 | 0.0327 | 0.0364 | 0.039 | 0.0376 | 0.027 | 0.0293 | 0.0296 |

| 8 | 50.24 | 0.371 | 0.36 | 0.36 | 0.422 | 0.397 | 0.0248 | 0.0282 | 0.0304 | 0.0288 | 0.0207 | 0.0224 | 0.0226 |

Temperature Factor of the Resistivity

Grade |

20℃ |

100℃ |

200℃ |

300℃ |

400℃ |

500℃ |

600℃ |

700℃ |

800℃ |

900℃ |

1000℃ |

1100℃ |

1200℃ |

1Cr13A14 |

1 |

1.005 |

1.014 |

1.028 |

1.044 |

1.064 |

1.09 |

1.12 |

1.132 |

1.164 |

1.172 |

1.18 |

1.186 |

0Cr25A15 |

1 |

1.002 |

1.005 |

1.008 |

1.013 |

1.021 |

1.03 |

1.038 |

1.04 |

1.042 |

1.044 |

1.049 |

1.047 |

0Cr21A16 |

1 |

1 |

1.002 |

1.006 |

1.011 |

1.02 |

1.037 |

1.043 |

1.046 |

1.049 |

1.052 |

1.055 |

1.058 |

0Cr21A16Nb |

1 |

0.997 |

0.996 |

0.994 |

0.991 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0.99 |

0Cr27A17Mo2 |

1 |

0.992 |

0.986 |

0.981 |

0.978 |

0.976 |

0.974 |

0.972 |

0.97 |

0.969 |

0.968 |

0.968 |

0.967 |

Cr20Ni80 |

1 |

1.006 |

1.012 |

1.018 |

1.025 |

1.026 |

1.018 |

1.01 |

1.008 |

1.01 |

1.014 |

1.021 |

1.025 |

Cr15Ni60 |

1 |

1.011 |

1.024 |

1.038 |

1.052 |

1.064 |

1.069 |

1.073 |

1.078 |

1.088 |

1.095 |

1.109 |

|

Cr20Ni30 |

1 |

1.023 |

1.052 |

1.079 |

1.103 |

1.125 |

1.141 |

1.158 |

1.713 |

1.187 |

1.201 |

1.214 |

1.226 |