- Heater

-

- Cartridge Heaters

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

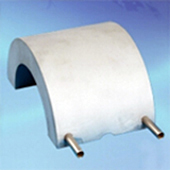

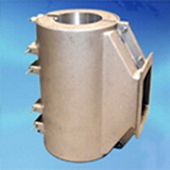

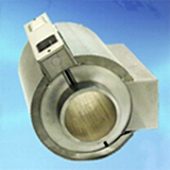

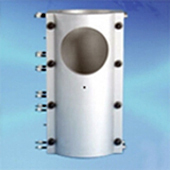

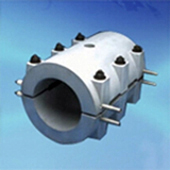

Cast in heaters

The cast in heaters are composed of one or more electrical heating elements embedded in an aluminum alloy, brass, bronze, copper-nickel or iron type material with excellent thermal conductivity.

The gravity casting provides excellent homogeneity of the casting material and therefore allows excellent thermal diffusion. The regularity of the surface temperature is ensured by a suitable forming. The cast heating elements can be used to surface temperatures up to 950 ° C.

Cast in aluminum heaters

Aluminum alloy is the most commonly used material up to a temperature of 400 ° C. For higher temperatures, or because of mechanical stress or specific environmental constraints, it is replaced by alloys of brass, bronze or cast iron.

The cast in heating devices are machined according to drawings taking into account roughness requirements.

Features

Features

- High operating temperatures

- Liquid cooling or air-cooling fins

- Any size or shape available

- Pressure casted ensure porosity free high density casting

- Extremely ruled and resistant to damage

- Precise and accurate control of temperature due to heat cool action

- High watt density available

Specifications:

Specifications:

Size |

As required any size possible |

Voltage |

120, 240, 380, 415 volts |

Max. Wattage |

Aluminum 5w/cm² |

Bronze 7w/cm² |

|

Terminations |

Leads, Terminal boxes, Screw |

Max. Temperature |

Aluminum 371℃ |

Bronze 760℃ |

|

Iron 482℃ |

|

Options |

Holes, Grooves, Notches, Cutouts |

Applications:

Applications:

1 |

Vacuum forming |

2 |

Pressure assist forming |

3 |

Drape and press forming |

4 |

Barrel and sprue bushing heating |

5 |

Hopper heating |

6 |

Manifold heating |

7 |

Hot runner systems |