- Heater

-

- Cartridge Heaters

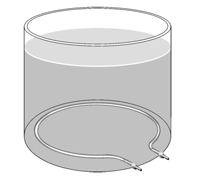

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

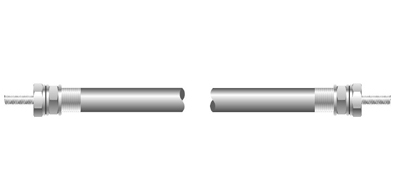

Tubular heater

Tubular Heaters are the most versatile and widely used source of electric heat for industrial, commercial and scientific applications. They can be designed in a wide range of electrical ratings, diameters, lengths, terminations, and sheath materials. Also screw plug immersion heaters, flanged immersion heaters, circulation heaters, and high temperature process air heaters are available. Hongtai engineering is available to assist with the design and development of special heaters for particular requirements.

Features

Features

1. Selected high quality sheath materials (see table below for selection).

1. Selected high quality sheath materials (see table below for selection).

2. Precision helical wound nickel-chrome resistance wire.

3. High purity magnesium oxide powder compacted to provide maximum heat

conductivity and optimum dielectric strength.

4. Integral cold pin fusion welded to helical resistance wire provides optimum

current carrying capacity.

5. Threaded screw terminal with ceramic or mica insulator provides a positive connection from lead wire to terminals.

Tubular Heater Standard Sheath Materials

Tubular Heater Standard Sheath Materials

The following are the most common tubular element sheath materials. For other materials consult Hongtai.

Material |

Material Max. Temp. °C |

Application |

Copper |

150 |

Water, non-corrosive liquids |

Steel |

400 |

Oil immersion |

Stainless Steel 304 |

650 |

Water,Corrosive liquids, food processing |

Stainless Steel 316 |

650 |

Corrosive liquids, |

Stainless Steel 321 |

650 |

intergranular corrosion situation |

Incoloy 800 |

800 |

Water ,Corrosive liquids, air, clamp on |

Physical And Electrical Specifications

Physical And Electrical Specifications

Sheath Dia. ±0.15mm |

6.4 |

8 |

10 |

12 |

14 |

16 |

18 |

20 |

25 |

Sheath Length Max. (mm) |

6000 |

6000 |

6500 |

6500 |

7000 |

7000 |

7000 |

7000 |

7000 |

Maximum Voltage |

250 |

277 |

480 |

550 |

550 |

550 |

550 |

550 |

550 |

Wattage Tolerance |

+5% -10% |

||||||||

Resistance Tolerance |

+10% -5% |

||||||||

For Various Shape, please Click Here