- Heater

-

- Cartridge Heaters

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

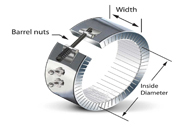

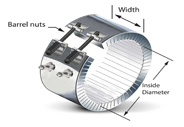

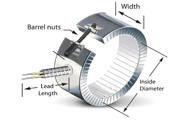

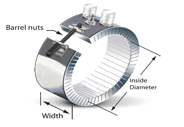

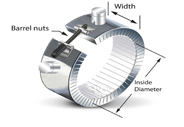

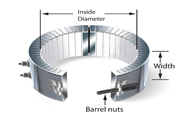

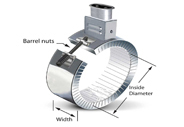

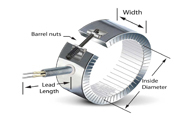

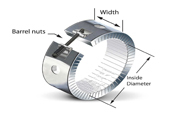

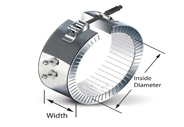

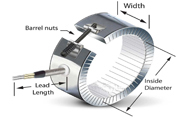

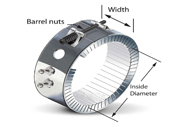

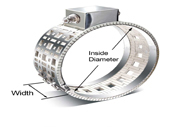

Ceramic band heater

Ceramic band heaters are medium-to-high temperature heaters that have 600℃as a maximum working temperature. They provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications.

Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. Hongtai engineering is available to assist with the design and development of special heaters for particular requirements.

Ceramic band heaters are medium-to-high temperature heaters that have 600℃as a maximum working temperature. They provide long life and use less wattage (because of insulation) in plastics extrusion and injection molding applications.

Ceramic band heaters are available with different terminal styles, are fully flexible, and can accommodate holes and cut-outs. Hongtai engineering is available to assist with the design and development of special heaters for particular requirements.

Features:

Features:

- Stainless Steel sheath resists rust and high temperatures, and provides firm mechanical support.

- Ceramic insulation prevents heat loss, thereby lowering energy costs.

- High temperature nickel-chromium element wire

- Max. watt density : 6 W/cm² (Wattage tolerance: +5% -10%)

- Mini diameter: 60mm

- Mini height: 25.4mm

- Thickness: 12mm

- Standard gap: 9mm

Advantages and applications:

Advantages and applications:

Advantages |

Applications |

Reduce power consumption |

Injection molding |

Conserve heat |

Blow-molding |

High degree of flexibility |

Plastic extrusion |

Uniform heat distribution |

Container, pipe, or tank heating |

Various termination styles |

Process applications |

Various types

Various types

Ceramic band heaters can be manufactured with different clamping mechanisms, terminations styles, holes and cut-outs.

Clamping Styles |

Termination Styles |

Flange lock-up |

Terminal box |

Post terminals |

|

Latch & trunion |

Straight armor cable |

Stainless steel braid |

|

Barrel nuts |

European style straight plug |

European style 90° plug |