- Heater

-

- Cartridge Heaters

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

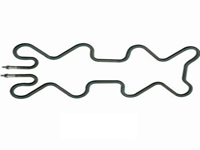

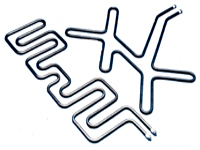

Manifold Heater

Also known as formed tubular heaters or flexible heaters, these heaters are mainly used for Hot Runner manifolds. It is supplied in Chrome Nickel Steel with nominal sheath diameter of 6.50mm and 8.00mm. Standard elements have a terminal post which gives a cold section of approx 30mm for 6.50mm and 35mm for 8.00mm.The helical wound heating wire is made of a high temperature resistant NiCr alloy. And the insulation consists of superior grade of magnesium oxide (MgO). As the heaters are swaged, even at high sheath temperature they have excellent electrical insulation and a high heat transfer. To prevent the heater from moisture the connection ends are sealed with sealing components. For manufacturing formed elements it is necessary to have an accurate dimensional sketch showing all the centre distances, radius and degrees.

Features

Features

- Available in Chrome Nickel Steel

- Sealed Edges to prevent from Moisture

- Superior Grade Magnesium Oxide Insulation

- Swaged for Good Electrical Insulation & Heat Transfer

- Available in Dia 8.5 mm, 8 mm,6.5 mm & square section 6 mm x 6 mm

-

Length

300 -1550mm

400 - 2100mm

Maximum Current

12 A

15 A

Nominal Voltage

< 230V

< 400V

Wattage

±10%

±10%

Dielectric Strength

1.5 HV

1.5 HV

Insulation MΩ

>5Ω

>5Ω

Leakage Current

<0.5 mA

<0.5 mA

Minimum Unheated

30mm

35mm

Terminal Pins

M3 x .50mm/ Plain post

M4 x .70mm

Length Tolerances: ± 2%

Diameter Tolerance: ± 0.10mm