- Heater

-

- Cartridge Heaters

- Tubular Heaters

- Air Finned Heaters

- Flange Immersion Heaters

- Screw Plug Immersion Heaters

- Coil Heaters

- Manifold Heaters

- Mica Band Heaters

- Ceramic Band Heaters

- Brass Nozzle Heaters

- Cast In Heaters

- Flexible Ceramic Pad Heater

- Silicone Rubber Heaters

- Ceramic Heaters

- FIR Tube Heaters(Blackbody Heaters)

- Quartz Heaters

- Heater Accessory

- Temperature Sensors

- Alloy

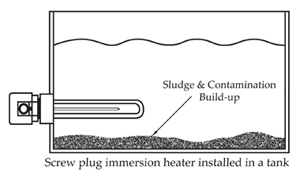

Screw Plug Immersion heater

Screw Plug Immersion Heaters are screwed directly through a threaded opening in a tank wall or through a matching pipe coupling or half coupling. Sizes of screw plug heaters are available with 1", 1-1/4", 1-1/2", 2", 2-1/2" pipe threads. A wide selection of screw plug sizes, kilowatt ratings, voltages, sheath materials, terminal enclosures and thermostats makes these compact heaters ideal for all types of applications.

Applications

Applications

Screw Plug Immersion Heaters are used for heating liquids and gases in a variety of processes. These heaters are ideal for process water heating and freeze protection. All types of oils and heat transfer solutions can also be heated using these compact, easily controlled units. The direct immersion method is energy efficient and well suited for many applications.

- Hot Water Storage Tanks

- Warming Equipment

- Preheating all Grades of Oil

- Food Processing Equipment

- Cleaning and Rinsing Tanks

- Heat Transfer Systems

- Process Air Equipment

- Boiler Equipment

- Freeze Protection of Any Fluid

Screw Plug Orientation with Thermowell

Screw Plug Orientation with Thermowell

Normal size for reference ,pleaseClick Here.

How to Order

How to Order

To place an order, or get a quotation, please provide the information itemized below. Contact Hongtai factory for further assistance.

- Electrical Rating...................................Voltage, phase, Wattage

- Screw Plug Size and Material...........1", 1 ¼", 1 ½", 2", 2 ½" NPT or other size and standard; brass, steel, 304SS or 316SS

- Element Sheath Material....................Copper, Steel, 304SS, 316SS, Incoloy® or other

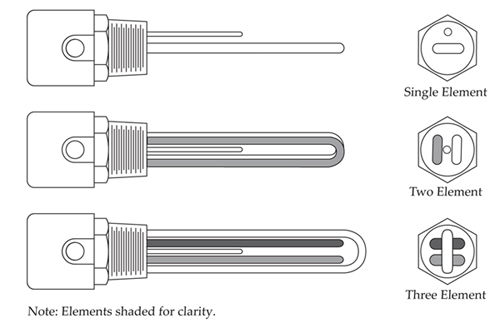

- Element Diameter and Quantity.......Provide element diameter and quantity (one, two or three).

- Element Watt Density..........................8, 16, 23, 48 or 60 W/in2, or other watt density value

- Immersion Length............................... Provide desired immersion length or maximum length allowable.

Also our engineer can help you to design the heaters, contact Hongtai for details.

Application Guidelines

Application Guidelines

The goal is to optimize the heater configuration to ensure the longest life possible, while minimizing overall product and life cycle costs. The general temperature, sheath material and watt density guidelines below can aid in proper heater selection for some common liquids. Contact us for further assistance.

Liquid |

Max. Operating Temps °F (°C) |

pH Level and/or Concentration |

Recommended Sheath Material |

Typical Plug Material |

Max. Watt Density W/in2 (W/cm2) |

Clean, Potable Water |

212 (100) |

Neutral (pH 6 to 8) |

Copper/304SS |

Brass/304SS |

60-90 (9.5-14) |

Process Water & Weak Solution |

212 (100) |

pH 5 to 9; 2-3% |

Incoloy®, 304SS |

Steel or 304SS |

48 (7.5) |

Demineralized, Deionized Water |

212 (100) |

Neutral |

304SS or 316SS (passivated) |

304SS or 316SS |

60 (9.5) |

Weak (Acidic) Solutions* |

210 (100) |

Up to 5-6% |

Incoloy®, 316SS |

Steel |

48 (7.5) |

Mildly Corrosive (Acidic) Solutions* |

180 (80) |

5-15% |

Incoloy®, 316SS |

304SS or 316SS |

20-30 (3.5) |

Severely Corrosive (Acidic) Solutions* |

180 (80) |

>15% |

Incoloy®, titanium, PTFE |

304SS or other |

15-16 (2.5) |

Caustic Soda 10% |

200 (100) |

pH 14; 10% |

Incoloy® |

Steel |

20-23 (3.5) |

Caustic Soda 50% |

250 (120) |

pH 14; 50% |

Incoloy® |

Steel |

16 (2.5) |

Fuel Oil 1 & 2; Kerosene Lube Oil SAE 10 to 30 |

200-250 (95-120) |

- |

Steel |

Steel |

20-23 (3.5) |

Fuel Oil 4 & 5; Lube Oil SAE 40 to 50 |

200-250 (95-120) |

- |

Steel |

Steel |

15-16 (2.5) |

Fuel Oil 6 & Bunker C |

160 (70) |

- |

Steel |

Steel |

6-8 (1.2) |

Hydraulic Oil |

100 (40) |

- |

Steel |

Steel |

15-16 (2.5) |

Ethlyene Glycol |

300 (150) |

- |

Steel |

Steel |

23-30 (3.5-4.5) |

Glycerine |

500 (260) |

- |

Incoloy® |

Steel |

8-10 (1.5) |

Molton Salt Bath |

800 (425) |

- |

Steel, 321SS, |

Steel |

23-30 (3.5-4.5) |

Paraffin Wax |

150 (65) |

- |

Steel or 304SS |

Steel |

15-16 (2.5) |

Molasses |

100 (40) |

- |

304SS or 316SS |

304SS |

4-5 (0.7) |

* Sheath material and watt density dependent on type of acid, concentration, temperature, aeration, movement, etc.

Please note that the user accepts full responsibility for validating that a heater is suitable for a given liquid or gas heating application.

Ensure that heater elements are completely covered in liquid AT ALL TIMES. Failure to do so may cause the heater elements to operate in open air and fail prematurely, or worse, lead to ignition of flammable vapor mixtures, causing serious personal injury and equipment damage. Liquid level sensors are highly recommended.

Hongtai recommends the use of a thermostat or process controller as well as a high limit sensor and FM approved safety controller to prevent unexpected over temperature conditions.

Other power,voltage,length,diamoter alse ok,please consult Hongtai for were details.